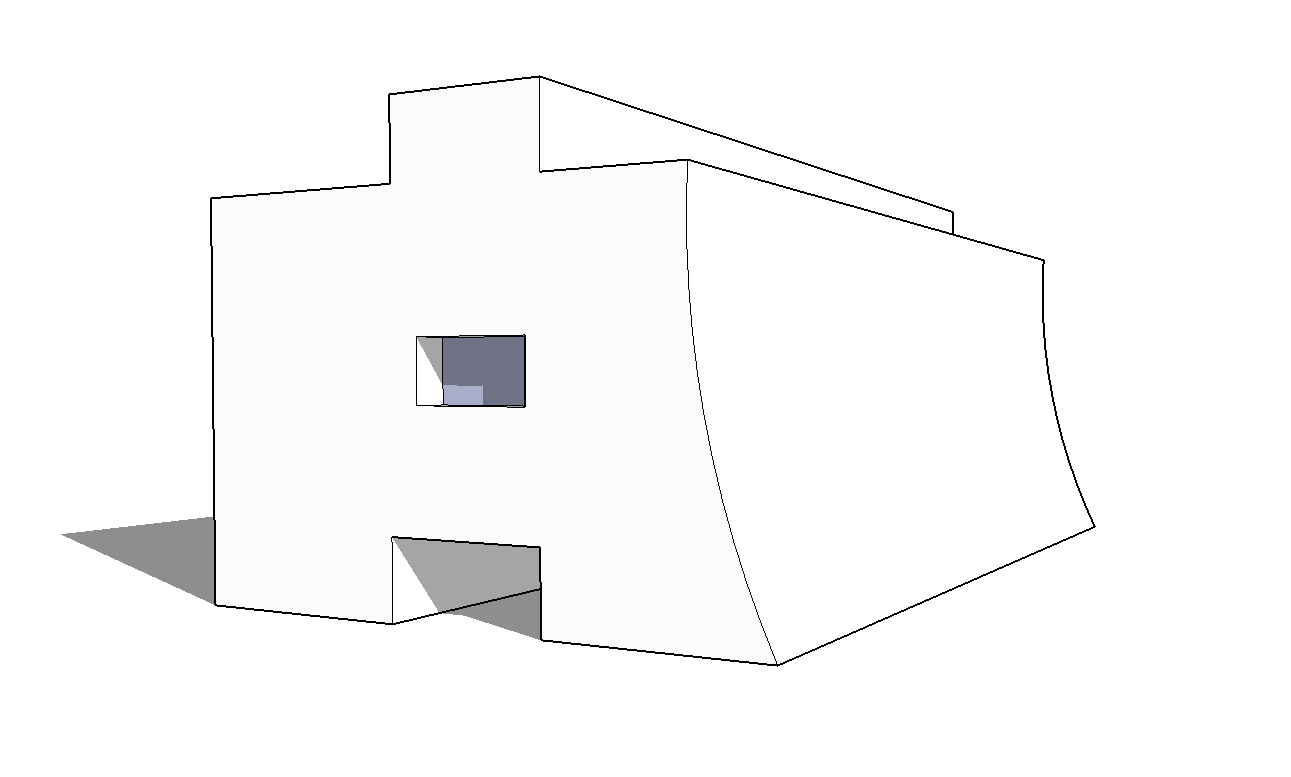

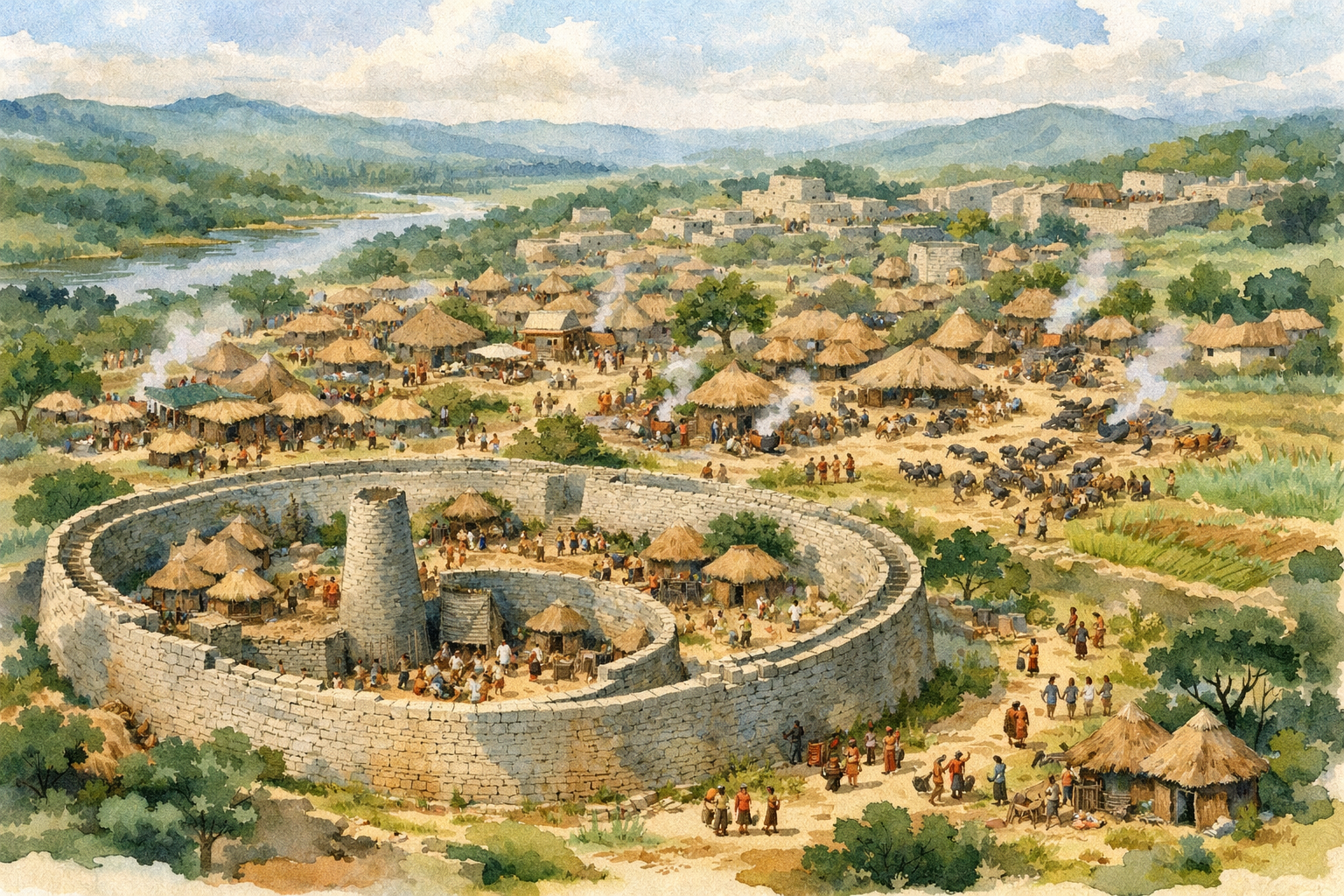

800 years. No mortar. Still standing.

Across southern Africa, over 200 dry-stone structures survive from the 11th-15th centuries. Great Zimbabwe housed 20,000 people. The walls—some 36 feet high—were built without mortar. They're still standing today.

Precision-cut stone, carefully stacked. Gravity and friction do the work. No mortar to crack. No plaster to fail. Water sheds off; the structure endures.

Vision

Extraordinary homes at reasonable prices. Built locally, by local people, with local materials. Good housing. Good jobs.

Market

Ghana's housing deficit exceeds 1.8 million units. Annual production falls short of demand.

| Current Deficit | 1.8 million units |

| Annual Production | ~40,000 units |

| Annual Need | ~200,000 units |

| Net Annual Shortfall | ~160,000 units |

At current production rates, the deficit grows each year.

Source: ConstructAfrica, Ghana Ministry of Works and Housing

Ghana has approximately 8.2 million households distributed across five income quintiles.

| Quintile | Households | Share of Income | Est. Annual Income |

|---|---|---|---|

| Q1 (Lowest 20%) | 1.64M | 4.7% | ~$700 |

| Q2 | 1.64M | 9.6% | ~$1,450 |

| Q3 | 1.64M | 14.8% | ~$2,230 |

| Q4 | 1.64M | 22.3% | ~$3,360 |

| Q5 (Top 20%) | 1.64M | 48.6% | ~$7,320 |

Top 10% holds 32.2% of national income.

Source: World Bank 2016

| Q5 Households | 1.64M |

| Q4 Households | 1.64M |

| Upper Q3 (estimate) | ~800K |

| Total Addressable | 2-4 million households |

Government "affordable housing" programs price units at $13,000-$42,550. These prices serve primarily Q5 households.

Source: Centre for Affordable Housing Finance in Africa

| Annual Remittances | $4.6 billion |

| Percent of GDP | 6.4% |

| Est. Housing Share | 25-35% |

| Annual Housing Flow | ~$1.2 billion |

Building a house back home is a significant life decision for the diaspora. Platforms like Seso Global and MyAwayHome address trust and oversight challenges for remote construction.

Source: World Bank Remittance Data

Feasibility

Laterite soil is abundant across Ghana. Compressed earth blocks have been proven at scale in East Africa.

| Soil Type | Laterite (iron-rich clay) |

| Coverage | Common across Ghana and West Africa |

| Current Use | Road construction, traditional building |

| Transport | Local sourcing reduces costs |

The material is already present. No imports required.

Compressed earth blocks and interlocking stabilized soil blocks have been used in East Africa for decades.

| Hydraform (South Africa) | Commercial-scale production, established supply chain |

| ISSB Programs (Uganda, Kenya) | 37,000+ homes built, 150,000 people housed |

| Housing Microfinance | $30M in loans, 76% borrowers under $10/day income |

| Block Type | Interlocking, dry-stack |

| Mortar Reduction | 70% less than conventional |

| Production | 400 blocks/day with manual press (3-person team) |

| Training | 5-day program |

Simple operation enables community participation and creates local jobs.

Field validation in Ghana requires:

| Soil Testing | Local composition analysis |

| Equipment | Production equipment adaptation |

| Compliance | Ghana building code documentation |

| Cost Verification | Production scale economics |

Strategy

Local partners bring local expertise. Developers license the system.

Two roles make this work:

| Role | Contribution | Outcome |

|---|---|---|

| Technical Partner | Local soil expertise, field validation, production oversight | Quality assurance |

| Developer | Capital, land, construction, sales | Licensed production rights |

The technical partner validates production for Ghana conditions. Developers build houses.

Developers license production rights for their territory.

| License Component | Description |

|---|---|

| Territory | Exclusive or non-exclusive by region |

| Training | Production methods, quality control |

| Equipment | Mold specifications for block production |

| Support | Technical guidance during startup |

License terms negotiated with qualified developers who demonstrate capacity.

| Stakeholder | What They Get |

|---|---|

| Technical Partner | Ongoing role, professional recognition |

| Developer | Proven system, competitive advantage, technical support |

| Market | Quality housing at reduced cost |

| Workers | Local jobs, transferable skills |

Everyone has aligned incentives. Success for one means success for all.

Budget

Local materials. Local labor. The economics work.

| Materials | Locally sourced laterite vs imported cement and steel |

| Labor | Community workers trained on-site |

| Transport | Reduced logistics cost from local sourcing |

| Equipment | Manual and semi-automated presses, locally serviceable |

Imported materials carry shipping, duties, and currency risk. Local materials do not.

| Block Production | On-site or near-site, eliminates transport markup |

| Mortar Reduction | 70% less than conventional masonry |

| Skill Requirements | 5-day training for production crew |

| Scale | Economics improve with volume |

Quality housing delivered through standard market channels. Pricing reflects market conditions.

Detailed budget available to qualified partners.

Patent

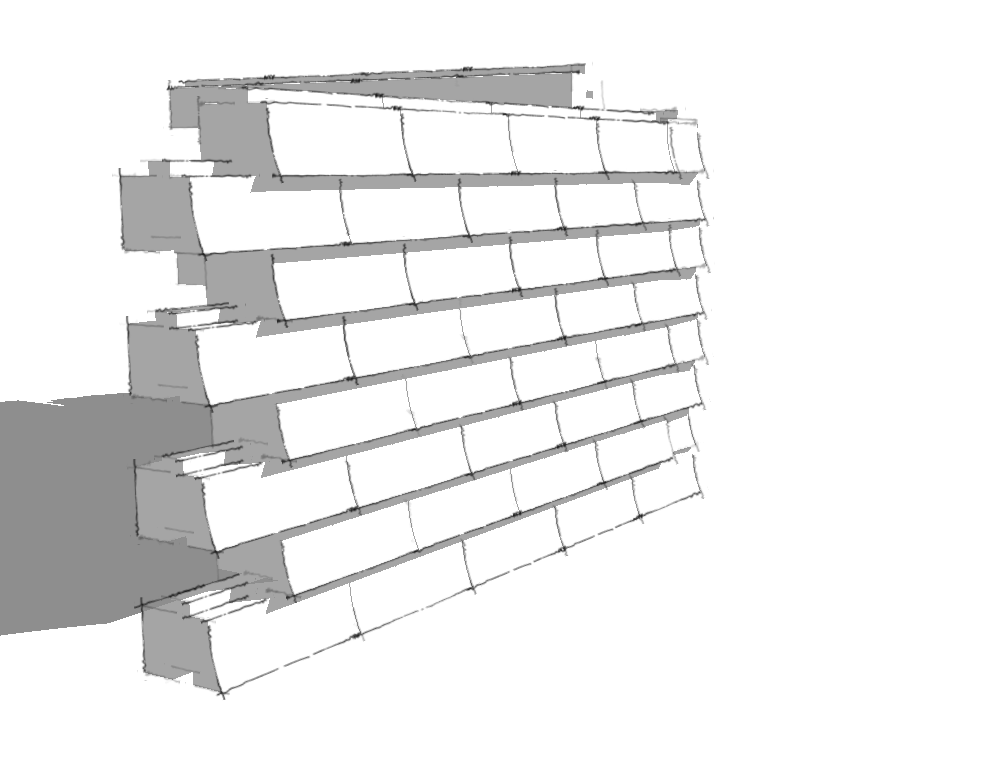

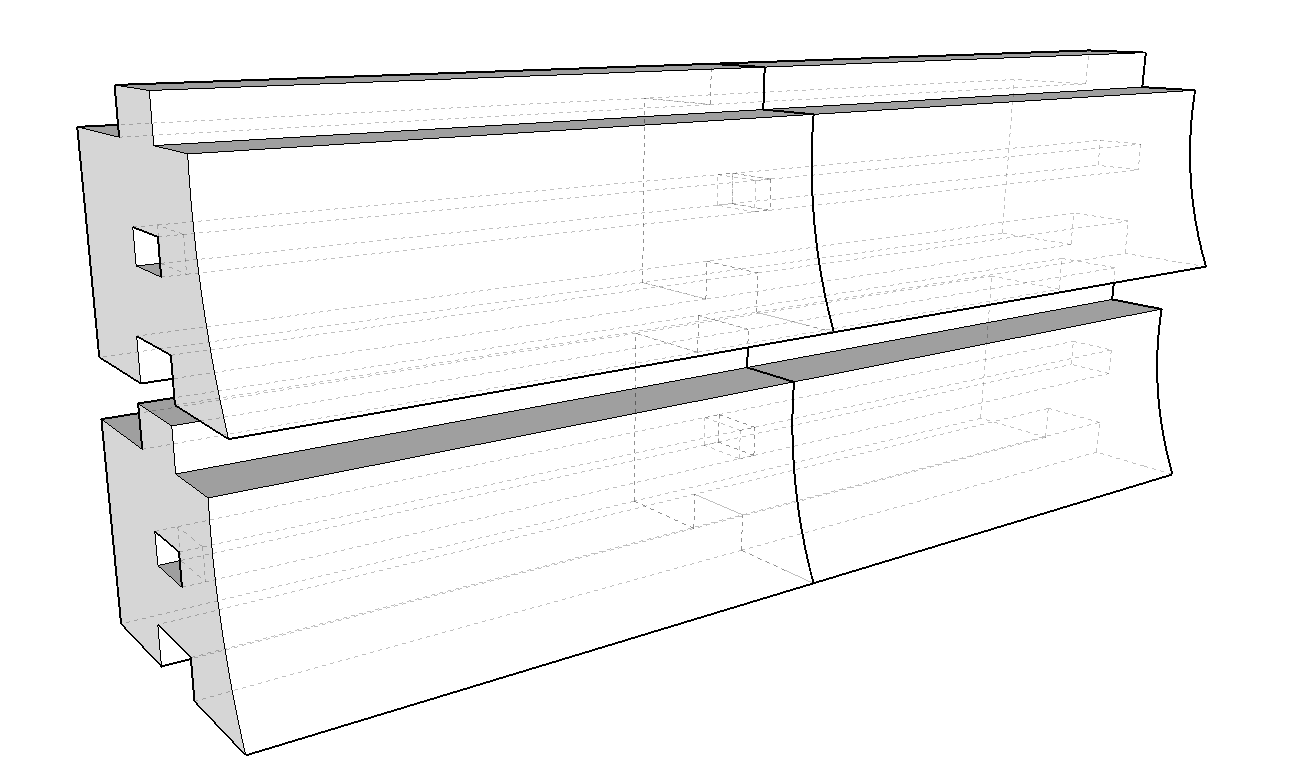

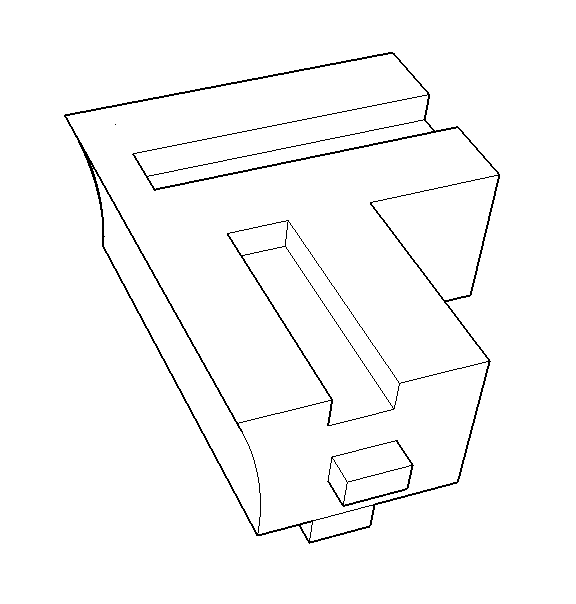

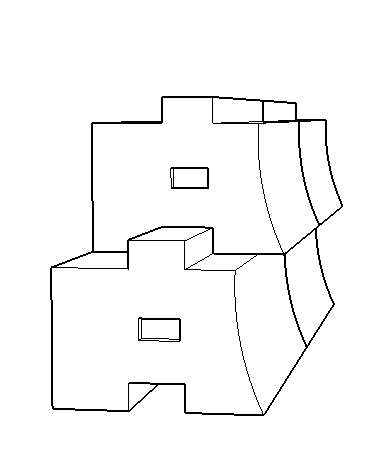

Patent-pending interlocking block with integrated water management.

An interlocking block geometry designed for dry-stack construction. The shape of each brick creates a slight overhang such that the course below is recessed, which gives water nowhere to enter.

| Four-Face Interlock | Upper rail tenon, lower rail mortise, end mortise, end tenon |

| Concave Water Shedder | Profile curves inward, directs water to drip edge |

| Overhang/Recess | Each course shelters the joint below |

| Block Types | Stretcher, Corner L, Termination |

Three mechanisms defeat water intrusion at every horizontal joint:

| Capillary Break | Recess exceeds wicking threshold |

| Surface Tension Break | Drip edge forces water to release |

| Gravity Drainage | Concave profile directs water outward |

Water follows the concave profile, releases at the drip edge, and falls free. It cannot reach the horizontal joint because the joint is tucked back under the overhang.

| U.S. Provisional | Application No. 63/955,346 |

| Filing Date | January 7, 2026 |

| Title | Interlocking Building Unit with Integrated Water Management Profile |

| Inventor | Michael Hoffman |

| Non-Provisional Deadline | January 7, 2027 |

The invention is geometry, not material. The water-shedding profile functions through geometric principles that apply regardless of material composition.

| Laterite | Common across Ghana and West Africa |

| Compressed Earth Block | Standard CEB and ISSB approach |

| Concrete | Conventional block production |

| Fired Clay | Traditional brick manufacturing |

| Other Materials | Any curable or formable material |

The patent covers the block shape. Use what's local.

Action Plan

Find the right technical partner. Everything else follows.

| Contact | Purpose |

|---|---|

| Technical Partner | Field validation lead, production oversight |

| University Connection | KNUST, University of Ghana - engineering faculty |

| Developer | Capitalist partner with land and construction capacity |

| Ghana Standards Authority | Building code compliance pathway |

| Phase | Activity | Outcome |

|---|---|---|

| 1 | Identify technical partner | Partnership agreement |

| 2 | Soil sampling and testing | Mix design validation |

| 3 | Block production trials | Strength verification |

| 4 | Pilot construction | Field validation |

| 5 | Developer licensing | Commercial scale-up |

| Partner Identification | Near-term |

| Production Validation | 3-6 months after partnership |

| Pilot Construction | 6-12 months after validation |

| Commercial Operations | Following successful pilot |

Timeline depends on finding the right partner. The rest is execution.

Start a Conversation

North Star Group

Contact